-

Stainless Steel Plate Sheet

-

Seamless SS Pipe

-

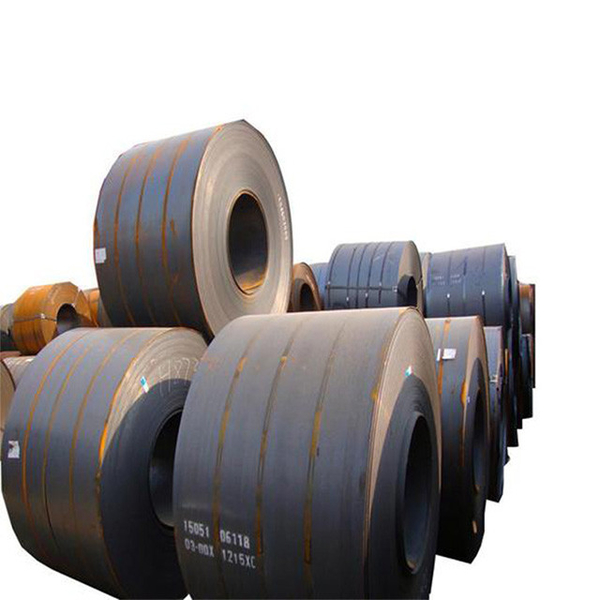

Stainless Steel Coil

-

Stainless Steel Flat Bars

-

Stainless Steel Pipe

-

Stainless Steel Round Bars

-

Stainless Steel Flat Strips

-

Stainless Steel Angle Bar

-

Prepainted Galvanized Steel Coil

-

PPGL Steel Coil

-

Galvanized Iron Pipe

-

GI Sheet Coil

-

Carbon Steel Profiles

-

Alloy Steel Seamless Pipe

-

Wear Resistant Steel Plate

Production Line

The company has three factories, with nearly eight years of production experience, focusing on coil, roundwood, plate, pipe, storage and processing, has a large number of high-quality management, technology and sales professionals, the introduction of a series of advanced processing equipment. Products are produced in strict accordance with GB, ASTM, EN, JIS and other national standards. We provide a variety of carbon steel, including high carbon, medium carbon steel, low carbon steel, bearing steel, tensile steel, heat resistant alloy, nickel alloy, special steel, non-ferrous metals and their alloys, alloy steel, low carbon alloy steel, stainless steel, to meet the requirements of different customers. Products are widely used in engineering, coal mine, textile, electric power, boiler, machinery, military and other fields.

![]()

The main raw materials for steelmaking are molten iron or pig iron with high carbon content and scrap iron. In order to remove impurities in molten iron, it is also necessary to add oxidizer, deoxidizer and slag-making materials to molten iron, as well as ferroalloys and other materials, to adjust the composition of steel. After the hot iron or pig iron with higher carbon content is added to the steelmaking furnace, the impurities in the hot iron are oxidized to remove after oxygen blowing, adding ore, decarburizing and other processes. Finally, the alloy is added to alloying, and the molten steel is obtained. There are three kinds of steelmaking furnaces: open hearth furnace, converter and electric furnace. The open hearth steelmaking method has been gradually phased out because of high energy consumption and poor operating environment. Bof and open hearth steelmaking is to preheat molten iron into the mixing furnace, add scrap steel into the bof or open hearth, and then mix the high temperature molten iron in the mixing furnace with the mixing car into the bof or open hearth for melting and heating. When the temperature is appropriate, it enters the oxidation stage. Eaf steelmaking is the process of adding cold scrap steel into eAF steel, melting and heating for a long time, and then entering the oxidation period.We have extensively participated in the construction of large-scale engineering projects such as airports, railways, ports and expressways in countries along the Belt and Road. The wire products are mainly exported to Thailand, Philippines, Indonesia, Malaysia, Singapore, Myanmar, Cambodia, Pakistan, Saudi Arabia, the United Arab Emirates, India and other countries and regions.

![]()

![]()