All Products

-

Stainless Steel Plate Sheet

-

Seamless SS Pipe

-

Stainless Steel Coil

-

Stainless Steel Flat Bars

-

Stainless Steel Pipe

-

Stainless Steel Round Bars

-

Stainless Steel Flat Strips

-

Stainless Steel Angle Bar

-

Prepainted Galvanized Steel Coil

-

PPGL Steel Coil

-

Galvanized Iron Pipe

-

GI Sheet Coil

-

Carbon Steel Profiles

-

Alloy Steel Seamless Pipe

-

Wear Resistant Steel Plate

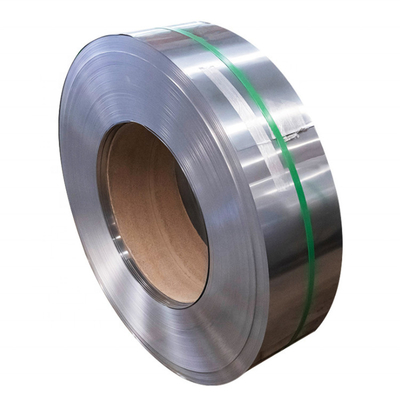

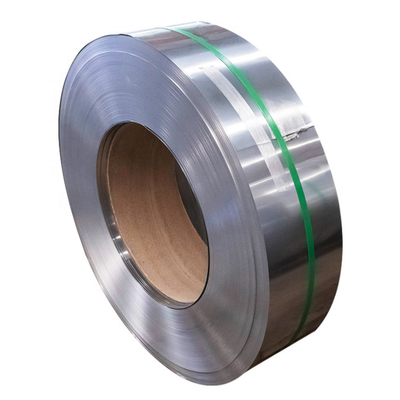

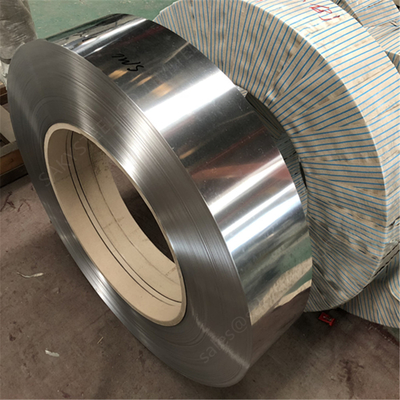

Slit Edge 5mm Stainless Steel Cold Rolled Coils 304 316 304L

| Place of Origin | CHINA |

|---|---|

| Brand Name | TISCO |

| Certification | ISO,SGS |

| Model Number | 304 316 304L 316L 410 420 |

| Minimum Order Quantity | 3 tons |

| Price | negotiable |

| Packaging Details | Standard export packing (waterproof paper + steel rings), or as your requirement |

| Delivery Time | ship within 10 days after received the advance |

| Payment Terms | T/T, L/C, Western Union |

| Supply Ability | 3000 tons per month |

Product Details

| Name | Stainless Steel Flat Strip/Coil/Band | Standard | AISI, ASTM, GB, EN, DIN, JIS |

|---|---|---|---|

| Grade | 304 316 304L 316L 410 420 | Thickness | 0.3-3 Mm Or As Request |

| Width | 10-1500mm | Length | 3-2000mm,or As Request |

| Technic | Cold Rolled Hot Rolled | Surface | No.1, 2b, Ba, Hl, 6K, 8K, PVD, Ti-Coated |

| Tolerance | ±1 | Application | Industry |

| Highlight | stainless steel slit coil 304 316 304L,5mm stainless steel slit coil,5mm stainless steel cold rolled coils |

||

Product Description

TISCO No. 1 Finished Cold Roll Slit/ Mill Edge JIS DIN TUV 304

316 304L 316L 410 420 5mm Stainless Steel Strip/Band

Product Description

Stainless steel strip is simply an extension of ultra-thin stainless steel plate.

It is a narrow and long steel plate mainly produced to meet the needs of the industrial

production of various metal or mechanical products in different industrial sectors.

| Grade | 201 | 202 | 304/304L | 316/316L | 310 | 321 | 409 | 430 | 439 | 410 | 2205 |

| Surface finishing | 2B, BA, NO.4, NO.6, 8K, HL, Etching, SB, Ti-coating etc. | ||||||||||

| Thickness | cold rolled 0.2~3mm, hot rolled 2.5-12.0mm | ||||||||||

| Width | 1000mm/ 1219mm /1250mm/ 1500mm | ||||||||||

| Length | As request | ||||||||||

| Itme | Surface finishing | Surface finishing methods | Main application |

| NO. 1 | HR | Heat treatment after hot rolling, pickling, or with treatment | For without the purpose of the surface gloss |

| NO. 2D | Without the SPM | Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing | General materials, building materials. |

| NO. 2B | After SPM | Giving No. 2 processing materials appropriate method of cold light sheen | General materials, building materials ( most of the goods are processed ) |

| BA | Bright annealed | Bright heat treatment after cold rolling, in order to be more shiny, cold light effect | Automotive parts, home appliances, vehicles, medical equipment, food equipment |

| NO. 3 | Shiny, coarse grain processing | The NO. 2D or NO. 2B processing timber No. 100-120 polishing abrasive grinding belt | Building materials, kitchen supplies |

| NO. 4 | After CPL | The NO. 2D or NO. 2B processing timber No. 150-180 polishing abrasive grinding belt | Building materials, kitchen supplies, vehicles, medical equipment, food equipment |

| 240# | Grinding of fine lines | The NO. 2D or NO. 2B processing timber 240 polishing abrasive grinding belt | Kitchen appliances |

| 320# | More than 240 lines of grinding | The NO. 2D or NO. 2B processing timber 320 polishing abrasive grinding belt | Kitchen appliances |

| 400# | Close to BA luster | The MO. 2B timber 400 polishing wheel polishing method | Building materials, kitchen utensils |

| HL (hair lines) |

Polishing line having a long continuous processing | In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line | The most common building materials processing |

| NO. 6 | NO. 4 processing less than the reflection, the extinction | NO. 4 processing material used for polishing Tampico brushing | Building materials, decorative |

| NO. 7 | Highly accurate reflectance mirror processing | No. 600 of the rotary buff with a polishing | Building materials, decorative |

| NO. 8 | Highest reflectivity mirror finish | Fine particles of abrasive material in order polishing, mirror polishing with a polishing | Building materials, decorative, mirrors |

![]()

![]()

![]()

APPLICATIONS

![]()

![]()

![]()

FAQ

Q1: Are you a factory or trading company?

A1: We are a Chinese manufacture of steel pipes with both factories and trading companies.

Q2.How can you ensure the quality of your product?

A2.All products have to go through three checks in the whole manufacturing process,it includes production,cutting sheets and the packing.

Q3.What is your delivery time and the supply ability?

A3.The delivery time normally within 15~20working days,we can supply about 15,000tons every month.

Q4.What kind of equipment in your factory?

A4.Our factory have advanced five-eighth roller rolling,cold rolling production equipment on the roll,advanced processing and testing equipment,which makes our product better quality with efficiency.

Q5.About the complaint,quality problem,etc aftersales service,how do you handle it?

A5.We will have certain colleague to follow our order accordingly for each order with professional after-sales service. If any claim happen, we will take our responsibility and compensate as per contract. For better serve our client, we'll keep tracing feedback of our products from clients and that's what make us different from other suppliers. We're customer care enterprise.

Recommended Products