-

Stainless Steel Plate Sheet

-

Seamless SS Pipe

-

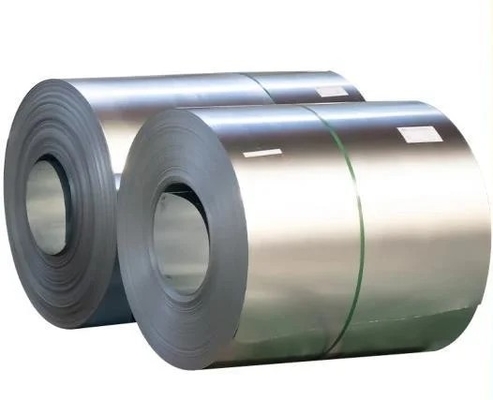

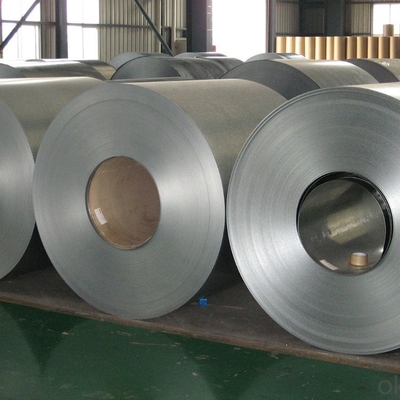

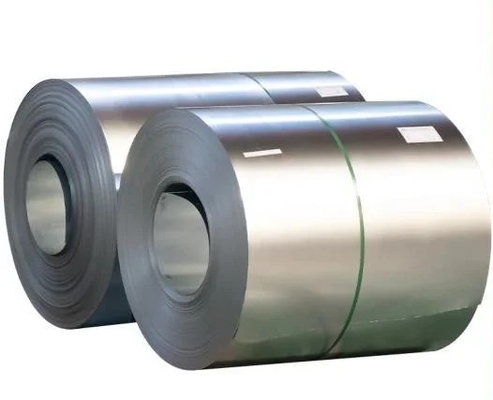

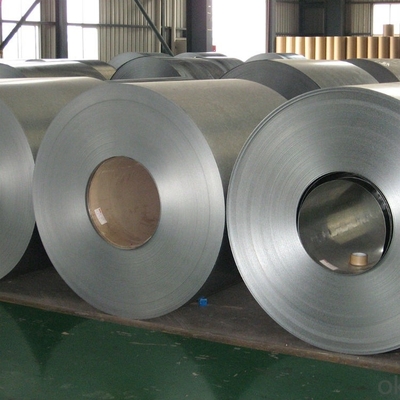

Stainless Steel Coil

-

Stainless Steel Flat Bars

-

Stainless Steel Pipe

-

Stainless Steel Round Bars

-

Stainless Steel Flat Strips

-

Stainless Steel Angle Bar

-

Prepainted Galvanized Steel Coil

-

PPGL Steel Coil

-

Galvanized Iron Pipe

-

GI Sheet Coil

-

Carbon Steel Profiles

-

Alloy Steel Seamless Pipe

-

Wear Resistant Steel Plate

Customized Gi Sheet Galvanized Steel Coil Hot Dip Dx51d G40 G60

| Place of Origin | CHINA |

|---|---|

| Brand Name | TISCO |

| Certification | ISO,SGS |

| Model Number | G550 G450 Dx51d |

| Minimum Order Quantity | 3 tons |

| Price | negotiable |

| Packaging Details | Standard export packing (waterproof paper + steel rings), or as your requirement |

| Delivery Time | ship within 10 days after received the advance |

| Payment Terms | T/T, L/C, Western Union |

| Supply Ability | 3000 tons per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Hot Dipped Zinc Coated Galvanized Steel Coil | Standard | ASTM, JIS, GB, AISI, DIN, BS |

|---|---|---|---|

| Grade | G550 G450 Dx51d | Thickness | 0.12-4mm |

| Width | 600-1500mm | Zinc Coating | 30-400GSM, As Your Request |

| Tolerance | ±1 | Application | Roofing, Exterior And Interior Wall |

| Highlight | Gi Sheet Galvanized Steel Coil,Dx51d Gi Galvanized Steel Coil,G60 Gi Galvanized Steel Coil |

||

Low Price Customized Size Hot Dip Dx51d G40 G60 Gi Sheet Galvanized Steel Coil

What is the difference between GI and hot-dip galvanized?

The key difference between galvanized and hot dip galvanized is that most galvanized materials have a smooth

and sharp finishing, whereas hot sip galvanized structures have a rough finishing. Galvanization is a process

of preventing metal surfaces from corrosion.

Does zinc coating prevent rust?

Nearly one half of all zinc produced is used in zinc galvanizing processes to protect steel and iron from rusting.

This involves coating the surface of a metal with a thin layer of zinc to create a corrosion-resistant barrier.

How long does zinc plated steel last?

Material is immersed in molten zinc at a temperature of around 450 degrees until the temperature of the work

is the same as the Zinc. During this process, the molten zinc reacts with the surface of the steel to form a series

of zinc/iron alloys. These alloy layers protect steel from corrosion for 30-40 years and more.

Product description

|

Name

|

Gi Coils Hot Dipped SGCC Dx51d Metal Zinc Galvanised Sheet Roofing Materials 275GSM 2mm Thick Z150 Z120 Z80 Regular Spangle Zinc Coated Galvanized Steel Coil

|

|

Grade

|

DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z, DX57D+Z, DC51D+Z, SGCC, SGCD, S220GD+Z, S250GD+Z, S280GD+Z, S320GD+Z, S350GD+Z, S550GD+Z

|

|

Width

|

600-1500mm

|

|

Thickness

|

0.12-4mm

|

|

Zinc coating

|

30-400g/m2

|

|

Surface treatment

|

chromated / oiled/slightly oiled/ dry

|

|

Hardness

|

soft, full hard, half hard

|

|

Spangle

|

zero spangle / minimized spangle / regular spangle/ big spangle

|

|

ID coil

|

508mm or 610mm

|

|

Coil weight

|

2-8 MT per coil. According to the customer's requirements

|

|

Package:

|

Standard export package (Plastic film in the first layer,second layer is Kraft paper. Third layer is galvanized sheet)

|

|

Application:

|

Industrial panels, roofing and siding for painting

|

|

Chemical Composition

|

||||||

|

GRADE

|

C

|

Si

|

Mn

|

P

|

S

|

Ti

|

|

SGCC/DX51D+Z

|

≤0.10

|

≤0.50

|

≤0.60

|

≤0.10

|

≤0.030

|

≤0.020

|

|

DX52D+Z

|

≤0.10

|

≤0.50

|

≤0.60

|

≤0.10

|

≤0.030

|

≤0.020

|

|

SGCD/DX53D+Z

|

≤0.10

|

≤0.30

|

≤0.50

|

≤0.05

|

≤0.030

|

≤0.020

|

|

SGCE/DX54D+Z

|

≤0.10

|

≤0.30

|

≤0.30

|

≤0.03

|

≤0.020

|

≤0.020

|

|

DX56D+Z

|

≤0.10

|

≤0.30

|

≤0.30

|

≤0.03

|

≤0.020

|

≤0.020

|

|

Structural

|

≤0.20

|

≤0.60

|

≤1.70

|

≤0.10

|

≤0.045

|

|

|

Mechanical Properties

|

||||||

|

GRADE

|

Yield Strength MPa

|

Tensile Strength MPa

|

Elongation %

|

|||

|

SGCC(DX51D+Z)

|

≥205

|

≥270

|

-

|

|||

|

SGCD(DX53D+Z)

|

-

|

≥270

|

38

|

|||

|

SGCE(DX54D+Z)

|

-

|

≥270

|

40

|

|||

|

DX56D+Z

|

-

|

≥270

|

42

|

|||

![]()

![]()

![]()

![]()

![]()

FAQ